FUTURE R

In response to the wave of Industry 4.0, robots are being applied in various fields of life and society, bringing significant changes to the economy. So, what is an industrial robot? What types of robots exist, and how are they applied in industrial production?

I. What is an Industrial Robot?

An industrial robot is a type of machinery that can perform tasks automatically, controlled by a computer or pre-programmed electronic microchips. They are typically programmed to carry out tasks such as assembly, production, or processing of products. Robots greatly assist humans, especially in harsh, toxic, or dangerous environments. They offer high precision and efficiency compared to manual labor.

II. Common Types of Industrial Robots Today:

- Palletizing Robots

Depending on the application, there are various types of palletizing robots, such as:- Stacking bags from the production line onto pallets.

- Stacking various types of containers.

- Arc Welding Robots

Depending on the intended use, there are many types of welding robots with various welding heads, including:- Arc welding.

- Wire welding.

- Spot welding.

- Laser welding.

- Welding robots are commonly applied in complex automated production lines requiring high specialization, such as in the production of cars, motorcycles, and pipelines.

- Pick and Place Robots

Pick and Place robots are used to move products from a fixed or mobile position to another location. These robots can operate in all stages of production, from supplying input materials to packaging finished products. They are particularly applied in the food, beverage, consumer goods, pharmaceuticals, and chemicals industries. - Foundry and Forging Robots

In the foundry industry, robots are responsible for pouring molten metal into molds, trimming excess edges, cleaning cast products, or enhancing the durability of products through sandblasting. With heat-resistant robotic arms made from special steel, they operate effectively even in high-temperature environments. - Milling Robots

Milling robots are used for rough processing, fine processing, and material removal in mechanical engineering, machinery manufacturing, electronics, interior design, construction, automotive, and many other fields. They are particularly useful in fields such as sculpture and scientific research. - Waterjet Cutting Robots

Waterjet cutting robots can cut various materials from metals (such as stainless steel, steel, and aluminum) to non-metals (plastics, ceramics, glass). Because this method does not generate heat, it is often used to cut heat-sensitive materials. Waterjet cutting robots are widely applied in the mechanical industry, construction, and aerospace. - Polishing Robots

Polishing robots are used to finish the surfaces of details and product components or to prepare surfaces for subsequent processes like painting or plating. They are applied in mechanical, metalworking, machinery manufacturing, interior design, and many other industries.

III. Major Benefits of Robots for Businesses:

- Cost Reduction and Improved Work Environment

Automating with industrial robots helps businesses reduce labor costs, recruitment, and training. Additionally, robots help minimize the risk of workplace accidents and facilitate compliance with safety standards. - Ensuring Consistency and Enhancing Product Quality

Robots help produce large quantities with high quality and consistency. Machinery operates with continuous precision, avoiding fatigue and loss of concentration like humans. - Increased Productivity

Robots can work continuously without needing breaks, optimizing production output. The production cycle is programmed to operate continuously without interruption. - Increased Flexibility in Production

Production lines utilizing robots can easily change processes, and products, and optimize operational stages through programming via controllers. - Material Savings and Reduced Product Costs

The application of robots helps reduce defective and damaged products. Materials are used accurately, minimizing waste, which in turn reduces product costs. - Enhanced Investment Efficiency

The use of robots helps optimize production space, reducing the need for area and infrastructure investment costs. - Enhanced Brand Reputation and Competitive Strength

With the superior benefits of robots, businesses can meet customer demands for quality and production timelines, thereby enhancing their reputation and competitiveness in the market.

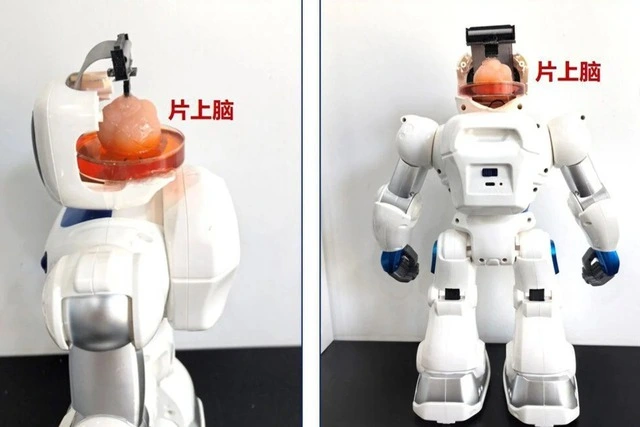

IV. Future R and the Future of Educational Robots

Future R is a company specializing in the development of educational robot products, aimed at supporting the learning and education of children. Although Future R does not directly produce industrial robots, its educational robot products still apply advanced and effective technologies, helping teachers and parents enhance the quality of education for students. Through continuous development and innovation, Future R is contributing to modernizing education and providing sustainable value for the younger generation.

Connect with us: [Fanpage] & [Website]

Reference: https://vuletech.com/ung-dung-cua-robot-trong-san-xuat-cong-nghiep/