FUTURE R

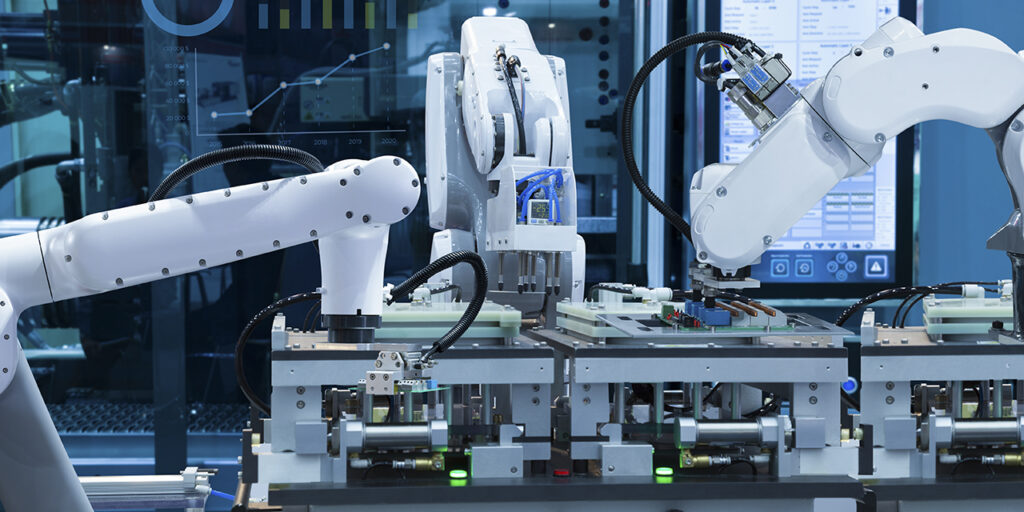

The application of robotic technology in manufacturing is bringing about significant changes to modern industry. Thanks to groundbreaking advancements in technology, especially in the context of the Fourth Industrial Revolution, robots have become indispensable tools in production lines. This not only improves efficiency and increases labor productivity but also addresses labor shortages and ensures worker safety in factories.

In the face of fierce competition from both domestic and international brands, alongside rising consumer demands for product quality and services, manufacturers must innovate and optimize their production processes. Therefore, integrating smart industrial robots combined with advanced technologies such as Artificial Intelligence (AI), cloud platforms, and big data has become an inevitable trend in modern production.

The Application of Robots in Manufacturing

Industrial robots are automated devices programmed to perform tasks with precision and consistency. Not only can they handle repetitive tasks, but robots can also perform jobs that require high accuracy, minimizing production errors and ensuring product quality. In many modern factories, robots have replaced much of human labor, creating products that are uniform and meet stringent standards.

Common Types of Industrial Robots in Manufacturing

- Robotic Arms with Machine Vision

Lightweight industrial robots with machine vision can observe and respond in real-time thanks to laser sensors and camera systems. These robots are often used in assembly lines, such as installing windshields in car production, improving accuracy and saving time compared to conventional robots. - Collaborative Robots (Cobots)

Cobots are compact robots capable of moving flexibly between areas within a factory. They are often used for transporting materials and components, reducing the risk of accidents and saving transportation time. - Industrial Robots for Heavy-Duty Work

These robots are programmed to perform tasks in harsh environments, such as painting or welding, minimizing dangerous jobs for humans and ensuring production efficiency.

Benefits of Using Industrial Robots

The application of robots in production not only enhances productivity but also significantly improves the quality of output. Due to their continuous and tireless work, robots help factories maintain uninterrupted production, meeting market demands without concerns about labor shortages. Moreover, robots contribute to improving the work environment by reducing workplace accidents and ensuring worker health.

One of the standout advantages of automation robots is their ability to mass-produce goods with uniform quality, meeting high precision standards. This allows businesses to scale production and increase competitiveness in the global market.

Challenges of Implementing Robots in Vietnam

Although the potential for robot applications in manufacturing is vast, businesses in Vietnam, particularly small and medium-sized enterprises, face numerous challenges in adopting this technology. One of the biggest hurdles is the investment capital required for modern robotic equipment. Additionally, the lack of a skilled technical workforce is another barrier preventing many companies from fully utilizing robotic technology.

Many factories in Vietnam still operate with outdated production lines or only partially apply automation, leading to inconsistencies in product quality and high production costs. This poses difficulties in competing with international competitors, who have already pioneered the adoption of new technologies.

The Future of Robotic Technology in Manufacturing

In the future, as technology continues to advance and the Vietnamese government introduces more supportive policies, the application of robots in production will become more widespread. This will create opportunities for Vietnamese businesses to keep pace with the trends of Industry 4.0, not only improving production efficiency but also enhancing product quality and market positioning internationally.

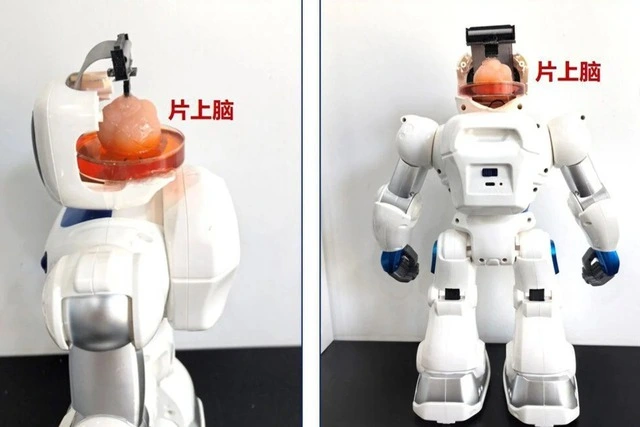

Besides the manufacturing sector, robotic technology is also being applied in various other fields, including education. Future R, a pioneer in developing smart educational robots, has been creating products that support parents and teachers in educating children. Future R’s products not only help children learn but also foster creative thinking and interaction with technology, contributing to improving the quality of education in the future.

Connect with us: [Fanpage] & [Website]

Reference: https://digital.fpt.com/linh-vuc/cong-nghe-robot-nganh-san-xuat.html